Leak Test & Plugging Solutions

We provides highly-engineered products and repair services for shell and tube heat exchangers, condensers, coolers and chillers. Our best known product, the Pop-A-Plug® Tube Plugging System, is the industry’s leading technology for plugging leaking and degraded heat exchanger tubes. We offer a range of test plugs, pressure testing and isolation plugs to greatly simplify and speed-up pressure testing and/or isolation of piping, tubing, valves, pressure vessels and a multitude of special applications.

Lifecycle Products & Services

Engineered products and comprehensive repair services for heat management cooling systems.

EST Group is a global manufacturer and designer of pipe and tube pressure testing and plugging equipments & systems that greatly simplify the maintenance of shell and tube heat exchangers and that speed-up in-service inspection of pipe, pipelines, piping systems and pressure vessels. We provides a comprehensive range of onsite services for heat exchanger troubleshooting and repair as well as turnkey pressure testing services..

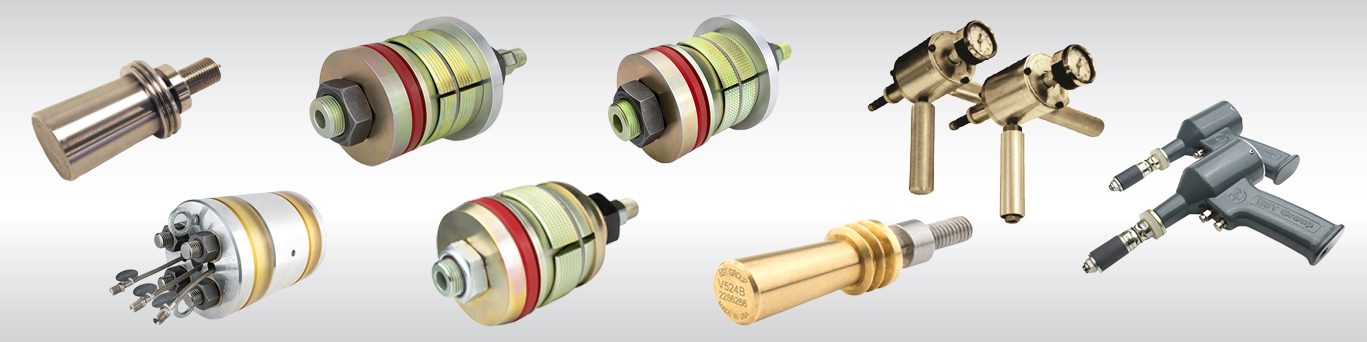

1): Pop-A-Plug® Tube Plugging System

EST Group offers a complete line of tube plugs and plugging systems designed for quickly preparing and plugging leaking heat exchanger, condenser and boiler tubes. Plugs are suitable for service in operating pressures up to 7,000 psi (480 Bar) and are designed to be installed without welding or explosives. A variety of systems and tools are available for installation and removal.

Pop-A-Plug® Heat Exchanger/ Condenser Tube Plugs

Pop-A-Plug® P2 High Pressure Tube Plugs

For quickly preparing and plugging leaking heat exchanger tubes. Seals at pressures to 7,000 psi (480 Bar) without welding or explosive.

For quickly preparing and plugging leaking heat exchanger tubes. Seals at pressures to 7,000 psi (480 Bar) without welding or explosive.

Pop-A-Plug® CPI/Perma Heat Exchanger Tube Plugging System

METHYL MERCURY ANALYSIS SYSTEM

For permanently sealing leaking heat exchanger tubes in seconds. Seals at pressures to 1000 psi (68.9 Bar) without damage to tubes or tube sheet.

.

For permanently sealing leaking heat exchanger tubes in seconds. Seals at pressures to 1000 psi (68.9 Bar) without damage to tubes or tube sheet.

.

Pop-A-Plug® Boiler Tube Plugs

For quickly preparing and plugging leaking boiler tubes. Seals at pressures to 1,000 psi (69 Bar) without welding.

For quickly preparing and plugging leaking boiler tubes. Seals at pressures to 1,000 psi (69 Bar) without welding.

Hydra-Loc™ Tube Sleeving

Effectively repair damaged tube ends in tubular heat exchangers and condensers without plugging or retubing.

Effectively repair damaged tube ends in tubular heat exchangers and condensers without plugging or retubing.

2): Hydrostatic Test / Isolation Plugs.

EST Group offers a complete line of hydrostatic test plugs and isolation plugs for pressure testing of pipe, pipelines and pressure vessels. Test plugs provide safe and effective testing at working pressures up to 14,000 psi (960 Bar). Pipe OD and ID sealing versions available..

Test Plugs

GripTight® High Pressure Test Plugs

I.D. Sealing Test Plug for high pressure hydrostatic testing of pipe, pipelines. Pressure vessels to 14,000 psi (960 Bar)..

I.D. Sealing Test Plug for high pressure hydrostatic testing of pipe, pipelines. Pressure vessels to 14,000 psi (960 Bar)..

GripTight® PE Test Plugs

For pressure testing of polyethylene pipe used in the gas distribution, water and wastewater industries.

For pressure testing of polyethylene pipe used in the gas distribution, water and wastewater industries.

OD GripTight® High Pressure Test Plugs

O.D. sealing test plug for high pressure hydrostatic testing of pipe, pipelines and pressure vessels to 5,000 psi (343 Bar).

O.D. sealing test plug for high pressure hydrostatic testing of pipe, pipelines and pressure vessels to 5,000 psi (343 Bar).

SQ2 High Pressure Test Plugs

For high pressure testing of small bore pipe and tubing at pressures to 6,500 psi (446 Bar).

For high pressure testing of small bore pipe and tubing at pressures to 6,500 psi (446 Bar).

Isolation Plugs

Isolation plugs are designed for quickly isolating and hydrostatically testing weld joints of any welded flange-to-pipe connection as well as isolating pipe ends during cutting, grinding and welding operations.

GripTight® Isolation Plug

Isolate and monitor potentially explosive vapors during "hot work", then effectively hydro test the new weld connection with one easy to use tool.

Isolate and monitor potentially explosive vapors during "hot work", then effectively hydro test the new weld connection with one easy to use tool.

Double Block & Bleed Isolation Plugs

Isolate pipe end hot work from potentially explosive upstream vapors; then weld and test the flange-to-pipe connection all with one tool.

Isolate pipe end hot work from potentially explosive upstream vapors; then weld and test the flange-to-pipe connection all with one tool.

High Lift Flange/Weld Test Plugs

For quickly isolating and hydrostatically testing the weld joint of any welded flange-to-pipe connection.

Also available are hydrostatic test pumps that are ideal for use with our entire range of pressure test plugs.

For quickly isolating and hydrostatically testing the weld joint of any welded flange-to-pipe connection.

Also available are hydrostatic test pumps that are ideal for use with our entire range of pressure test plugs.

Heat Exchanger Test Guns

Tube Testing Guns

For locating and identifying leaking heat exchanger tubes. G-Series are pneumatically actuated and pressurize individual tube or tube joint area to check for leaks.

For locating and identifying leaking heat exchanger tubes. G-Series are pneumatically actuated and pressurize individual tube or tube joint area to check for leaks.

G-650 Vacuum Joint Testing Gun

For locating and identifying leaking heat exchanger tubes. G-Series are pneumatically actuated and pressurize individual tube or tube joint area to check for leaks.

For locating and identifying leaking heat exchanger tubes. G-Series are pneumatically actuated and pressurize individual tube or tube joint area to check for leaks.