Acoustic Pyrometer

Gas temperature measurement

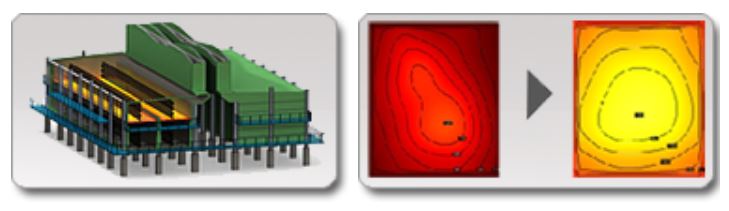

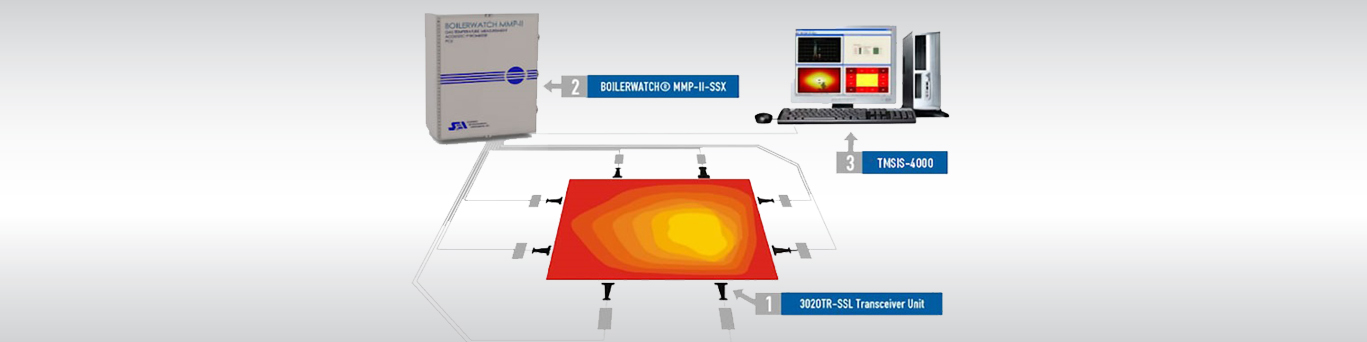

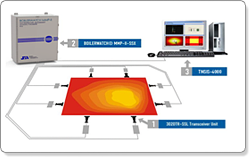

The BOILERWATCH MMP II-SSX acoustic pyrometer is an advanced industrial instrument that provides fully automatic measurement of high combustion-gas temperatures, permitting fuel trimming control within heaters & boilers. These systems are available in a variety of configurations & are easy to install, commission & operate.

SEI Acoustic Pyrometer, Online Continuous Gas Tempratures Measurement at Flue Gas Exit plane and other sections of the combustion chamber -

A True Device that can improve combustion efficiency and optimize boiler & Heaters operations results into low maintenance, increased up time, extended service life with efficient performance.

The result of these operational improvements is reduced NOx emissions, increased efficiency, reduced local slagging/fouling and corrosion, reducing localized hot spots and less carbon-in-ash.

Tube leak detection

This comes inbuilt with Noise / Leak Detection feature that allows you to view any abnormalities in the chart outside the normal acoustic parameters of the boiler / furnace and tube rupture process.

Monitor flue gas temperature from 32ºF to 3500 F (0ºC to 1927 C) for boiler start up preventing over firing that could damage superheat tubes or under firing that could potentially send wet steam to the steam turbine damaging buckets.

Boiler efficiency depends on good heat transfer rates. The transfer rate is improved by blowing gas on heat transfer surfaces to remove the combustion buildup (soot Blowing). It has been found that soot blowing losses can vary a great deal depending on the operator and type of coal burned.

This comes inbuilt with Noise / Leak Detection feature that allows you to view any abnormalities in the chart outside the normal acoustic parameters of the boiler / furnace and tube rupture process.

Monitor flue gas temperature from 32ºF to 3500 F (0ºC to 1927 C) for boiler start up preventing over firing that could damage superheat tubes or under firing that could potentially send wet steam to the steam turbine damaging buckets.

Boiler efficiency depends on good heat transfer rates. The transfer rate is improved by blowing gas on heat transfer surfaces to remove the combustion buildup (soot Blowing). It has been found that soot blowing losses can vary a great deal depending on the operator and type of coal burned.

Gas temperature measurements can be used as a direct indication of soot buildup, by installing the BOILERWATCH MMP-II-SSX.

An accurate control of superheat temperature with single path at Superheater is important for efficient power plant operation.

The BOILERWATCH® MMP II-SSX acoustic pyrometer is an advanced industrial instrument that provides fully automatic measurement of high combustion-gas temperatures,

permitting fuel trimming control within heaters and boilers.

The system is completely non-intrusive, and operates on the principal that the speed of sound in a gas is proportional to the temperature of that gas.